Grit Size

24-80

(P40, P60, P80)

Suitable for rough/heavy-duty applications.

100-150

(P100, P120)

Suitable for for intermediate

Other grits are available on special request (Made to Order)

“Ideal Price-Performance Ratio”, but for “High Quality”, to provide the market most competitive products.

Product Descriptions

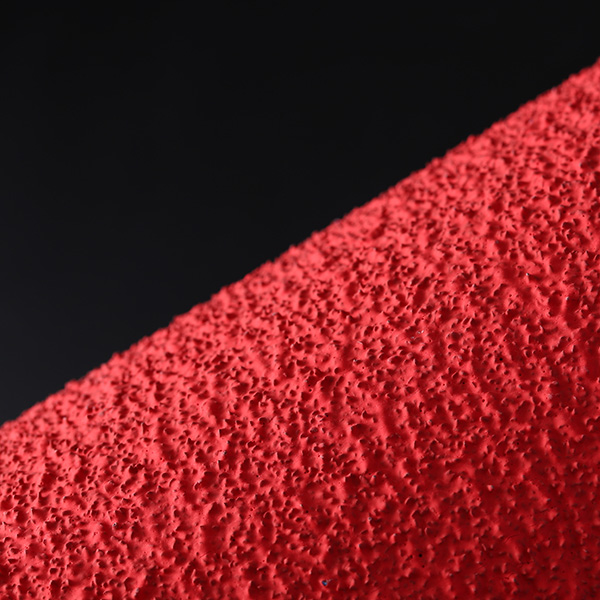

Self-sharpening CERAMIC ABRASIVE cloth is commonly used on stainless steels or unalloyed steels with an aggressive cut and a very long lifetime.

In order to further protect heat-sensitive alloys from heat-related stress cracks and discoloration, a grinding aid has been added to help lower grinding temperatures, making it ideal for industrial environments.

| Features | Benefits |

|---|---|

| Self-sharpening Ceramic Abrasive Grain | <<< Cooler Cut <<< Higher consistent stock removal rate thanks to constant recreation of sharp grain points; |

| Y-wt Sturdy Polyester Cloth Backing | Good stretch resistant; |

| The Tough Resin Bond | Can resist heat and offer exceptional adhesion of abrasive grains, ensuring outstanding performance in applications. |

| A Grinding Aid Added | <<< Can help reduce grinding temperatures, thus protecting heat-sensitive alloys such as stainless steel, nickel alloys, and titanium from discoloration <<< Can extend service life; |

Features

Material Usage

- Mainly for making sand belts, etc.

- Heavy deburring;

- Can be used for grinding Air jet blades, Low carbon steel, Nickel clad stainless steel plate, stainless steel, Heat sensitive alloys, Hammer heads, wood, Nickel alloys turbine blade, etc.

Applicable to