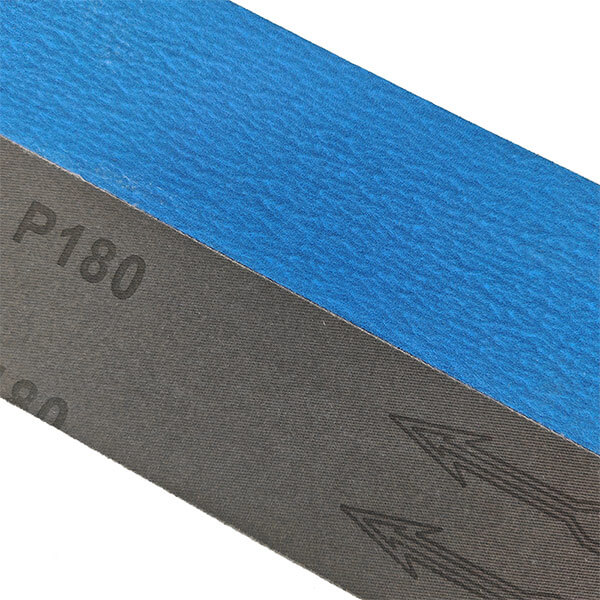

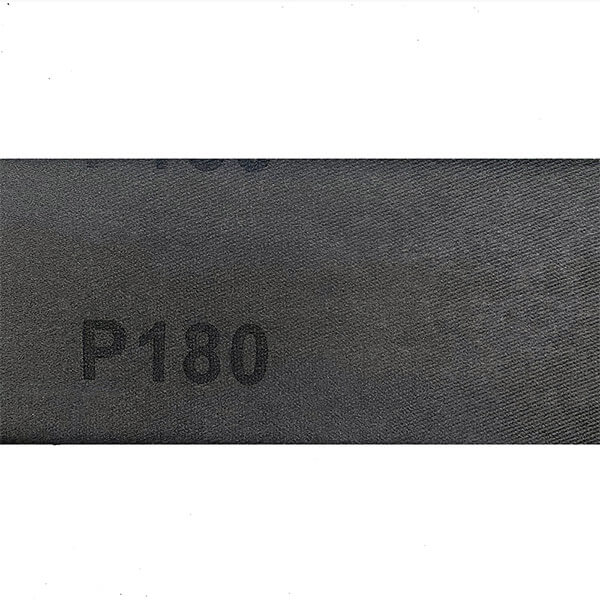

JS997 Ceramic Abrasive Cloth Belt For Metal Grinding

Description

GOLDEN SUN a wide range of coated abrasive belts for different industries, including narrow belts for a portable machine or wide belts for stainless steel coil finishing.

With the size ranging from 1/8″ wide to 600″ length in multiple grains and backings, we can deliver nearly any belt needed for your required application.

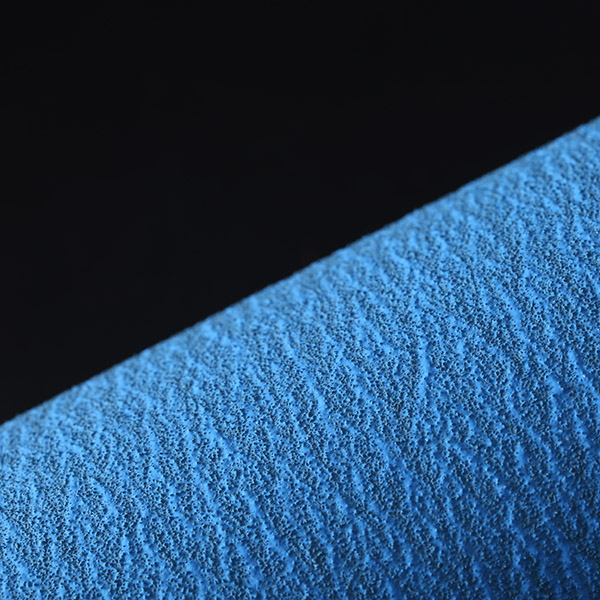

Ceramic Abrasive Sanding Belt made of JS997 is ideal for low contact pressure sanding.

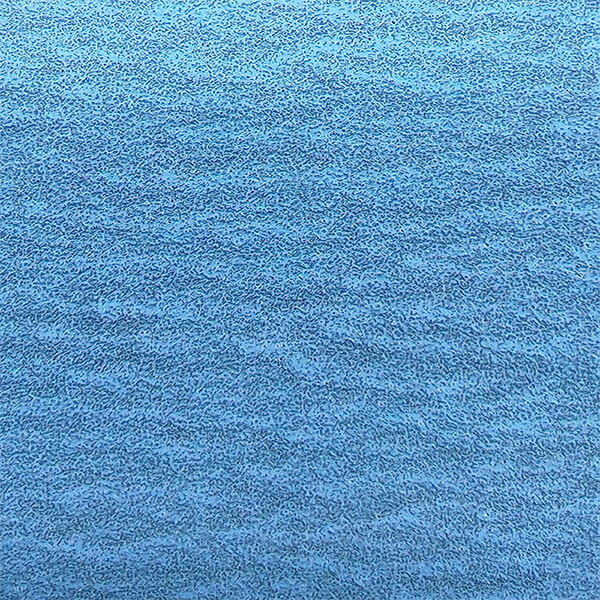

Its self-sharpening ability results in an extremely high stock removal rate due to continuous generation of new grain cutting edges over its entire belt life.

Features

- High consistent stock removal &Longer life span due to the self- sharpening ceramic alumina grain;

- Burn Free treatment added – for cool grinding of heat sensitive alloys such as stainless steel, nickel alloys and cobalt alloys that prevents heat-related stress cracks and discoloration and extends the belt service life;

- Flexible polycotton backing conforms to contoured parts for consistent finishing;

- Very good – performance ratio- Relatively lower total grinding costs.

Applications

- Used for grinding all kinds of metals, including Stainless Steel (SUS 400, 300) / Air Jet Blade / Heat sensitive Alloy / Low Carbon Steel / Hammer Head / Nickel and Stainless Steel plate and roll / Nickel Alloy Turbine Blade

Dimensions

| Overall Length (MM) | 2100mm |

| Overall Width (MM) | 50mm |

Other Specification Table

| W (MM) | L(MM) | Grit Range | Grain | Joints |

| 10-1350 | 330-7000 | 40#-600 | A/O | Lap/Butt Joint |

| 10-1350 | 330-7000 | 40#-600 | Special | Lap/Butt Joint |

| 50-1380 | 330-7000 | 24#-600 | Silicon Carbide | Lap/Butt Joint |

| 50-600 | 330-7000 | 36#-120# | ZA | Lap/Butt Joint |