Description

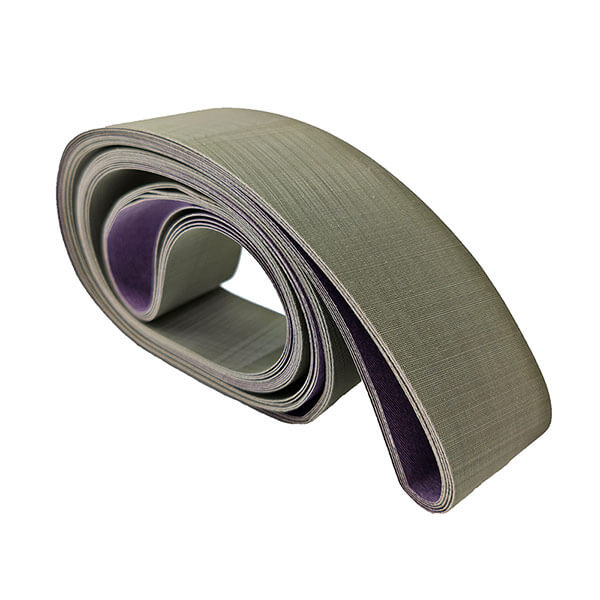

JINZTA Abrasive Belts feature a three-dimensional structure that is uniformly distributed over the entire surface of the belt, ensuring consistent performance and reducing variations between belts.

Unlike the conventional abrasives, which are randomly arranged minerals that start out sharp, but dull quickly;

The three-dimensional structures or pyramid -like structures consist of multiple layers of mineral that start out sharp, stay sharp throughout the life of the abrasive belt.

Features

- Self sharpening pyramids start sharp, stay sharp as the new layers of minerals are continually exposed to produce a consistent cut and fine finish;

- Flexible backing for consistent finish on contours;

- A thin Film Joint is chosen to minimize chatter marks, ensuring a smooth running belt, and consistent finishing effects.

- Three dimensional structure enables very consistent finishes throughout the abrasive life in robotic applications.

Applications

- Pre – grinding for removing scratches and spot welds on steel and stainless steel in preparation for mirror finishing;

- Ideal for intermediate finishing and fine polishing of all metals, including Aluminum, Stainless Steel, Titanium/Zirconium,High Nickel Alloy, Carbon Steel, Soft Metals, etc.

Grit Table

| JINZTA Grit | Conventional Grit |

| A3 | P5000 |

| A5 | P3000 |

| A6 | P2000 |

| A16 | P1200~P1500 |

| A30 | P600~P800 |

| A45 | P400 |

| A65 | P320 |

| A80 | P240 |

| A100 | P180 |

| A160 | P120 |

Dimensions

| Overall Length (MM) | 2100mm |

| Overall Width (MM) | 50mm |